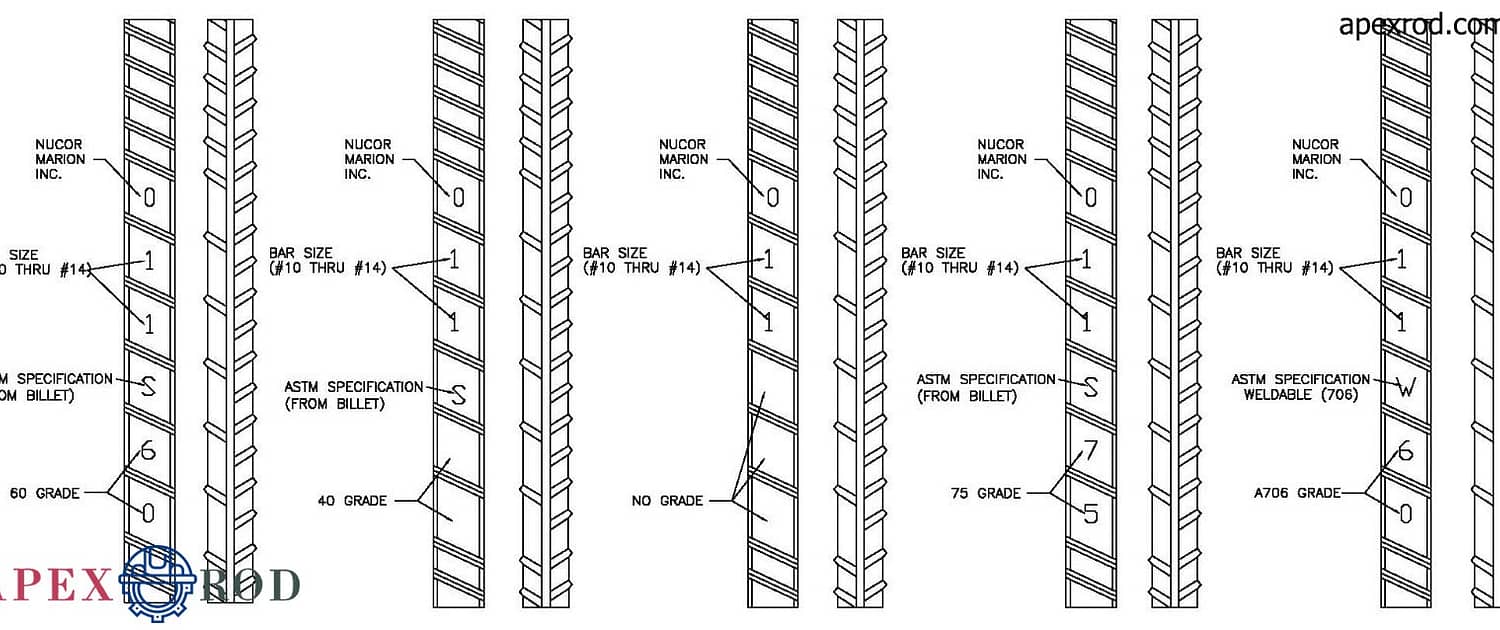

rebar manufacturer symbols

The Significance of Manufacturer Symbols in Rebar Industry

The rebar industry, integral to construction and infrastructure development, hinges significantly on the deciphering and understanding of manufacturer symbols on steel rebar. These symbols, often overlooked, serve as a vital communication tool between the manufacturer, contractors, and inspectors. Each logo engraved or rolled onto the surface of the rebar holds essential information about its origin, physical properties, and the quality assurance behind its production. This not only ensures compliance with regional and international standards but also instills confidence in the structural integrity of the construction projects.

Moreover, the significance of these symbols extends beyond mere identification. They are an essential aspect of quality control and traceability in the steel rebar supply chain. For instance, in cases of structural failure or during routine inspections, the ability to trace the rebar back to its manufacturer can be crucial in determining responsibility and understanding the cause of any issues. Furthermore, these symbols aid in the correct application of rebars, ensuring that the suitable grade, size, and type of rebar is used for specific structural requirements, thereby preventing potential construction hazards.

Lastly, in an increasingly environmentally conscious world, these manufacturer symbols can also indicate the sustainability practices of steel rebar production. Symbols may denote the use of recycled materials or adherence to low-carbon manufacturing processes, aligning with global efforts toward sustainable construction. Thus, the manufacturer symbols on rebars are not just identifiers; they are a gateway to understanding the entire lifecycle and impact of the rebar used in critical construction projects, emphasizing their indispensable role in the rebar industry.

Explanation of Rebar Marking Identification Chart

A Rebar Marking Identification Chart is an essential tool in the construction industry for understanding the specifications of reinforcement bars (rebars). This chart typically includes several key pieces of information that are stamped on the surface of rebars. These markings provide vital data such as the manufacturer’s identifier, the material grade, the size of the rebar, and sometimes additional information like the type of steel used or specific standards met. Understanding these markings is crucial for ensuring that the correct type of rebar is used in construction projects, thereby maintaining the integrity and safety of the structure.

Critical Elements in a Rebar Marking Identification Chart

Manufacturer’s Identifier: A symbol or series of letters representing the company that produced the rebar.

Material Grade: Indicates the strength of the rebar. Standard grades are 40, 60, and 75, which refer to the yield strength.

Size Number: A number that identifies the nominal diameter of the rebar.

Additional Symbols: These may include symbols for specific types of steel or manufacturing processes (e.g., “W” for low-alloy steel).

Quality Assurance in Rebar: Decoding Manufacturer Symbols

Quality assurance in the rebar industry is a pivotal aspect that ensures the safety and longevity of construction projects. A critical part of this quality assurance process involves understanding how to read rebar markings. These markings, stamped onto each piece of rebar, provide a wealth of information about the product’s origin, physical properties, and compliance with relevant standards. Deciphering these symbols is not just a matter of regulatory compliance but a step towards ensuring the structural integrity of any construction project.

The first step in decoding these markings is identifying the manufacturer’s symbol. This unique identifier is crucial as it traces the rebar back to its source, enabling accountability and quality tracking. Following this, the grade marking indicates the rebar’s yield strength – an essential factor in determining its suitability for specific structural applications. Understanding these markings helps contractors and inspectors verify that the rebar meets the necessary specifications and is appropriate for the intended use.

Moreover, additional markings may include the size of the rebar and specific details about the material composition and treatment process. For example, certain symbols might indicate whether the rebar is weldable or if it has been treated for enhanced corrosion resistance. This level of detail is vital in scenarios where environmental factors or specific structural demands require more specialized rebar characteristics. Therefore, the ability to accurately interpret rebar markings goes beyond essential compliance – it’s about ensuring the highest standards of safety and performance in construction projects.

Leave a Reply

Want to join the discussion?Feel free to contribute!