Metal Rebar and Structural Durability

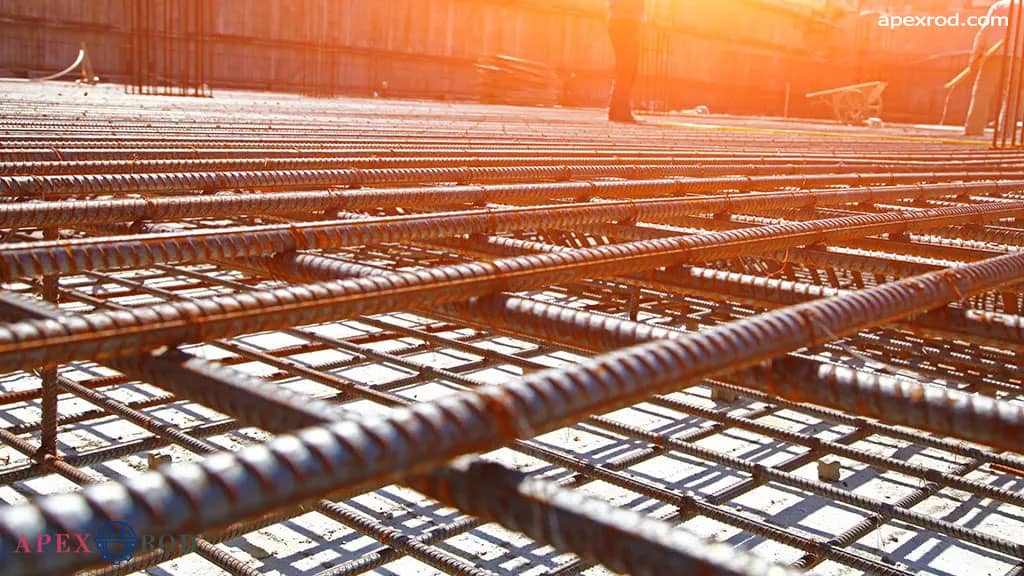

Metal rebar, a fundamental component in modern construction, is a steel bar or mesh of steel wires used to reinforce concrete structures. The origin of rebar goes back to the 19th century, with its usage becoming increasingly vital in the 20th century as buildings grew taller and systems more complex. Rebar, short for reinforcing bar, is made primarily from carbon steel and is characterized by ridges for better mechanical anchoring into the concrete. It significantly enhances the tensile strength of the structure, a property that concrete lacks on its own. Understanding the role and types of steel rebar is crucial for anyone involved in the construction industry.

The Importance of Rebar in Construction

The primary purpose of metal rebar is to provide additional strength to concrete structures. Concrete, while exceptionally strong under compression, is weak in tension. Rebar compensates for this weakness. By embedding metal bars within the concrete, the composite material can withstand more significant stress and loads, preventing cracking and collapse under tension. The ridges or deformations on the surface of the rebar create a stronger bond with concrete, ensuring that the two materials act cohesively under stress. The placement, size, and amount of rebar used in a project are carefully calculated based on the anticipated loads and stresses the structure will encounter.

Types and Applications of Metal Rebar

There are various types of metal rebar, each suited for specific applications. The most common is carbon steel rebar, known for its versatility and strength. Epoxy-coated rebar is used in structures vulnerable to corrosion, like those in marine environments. Stainless steel rebar, although more expensive, offers higher resistance to corrosion and is often used in exposed or critical structures. The application of metal rebar is not limited to large-scale buildings or bridges; it’s also used in roadways, foundations, and retaining walls. The type of rebar selected depends on the environmental conditions, load requirements, and longevity desired for the structure.

The History of Metal Rebar in Construction

The history of metal rebar in construction is a fascinating journey through time. Its origins can be traced back to the mid-19th century. Initially, builders used iron bars to reinforce structures, but it was in the late 19th century that steel, with its superior strength and flexibility, began to replace iron. The concept of reinforcing concrete with metal bars was revolutionary, addressing concrete’s inherent weakness in tension. The first recorded use of rebar was in the 1850s by French gardener Joseph Monier, who used iron rods to strengthen his concrete planters. This innovation marked the beginning of a new era in construction.

The Evolution and Advancements in Rebar Technology

Over the years, the use of metal rebar has evolved significantly. The early 20th century saw the introduction of standardized shapes and sizes for rebar, enhancing its practicality and efficiency in construction. The development of deformed bars with ridges for better adherence to concrete was a major advancement. During the 20th century, significant improvements were made in the quality and manufacturing of steel, leading to more robust and more durable rebars. The introduction of new materials like stainless steel and epoxy-coated rebar has further expanded its applications, especially in environments prone to corrosion. Today, metal rebar is an indispensable part of modern construction, integral to the strength and durability of countless structures around the world.

The Role of Metal Rebar in Enhancing Structural Integrity

Metal rebar for concrete plays a crucial role in enhancing the structural integrity of modern buildings and infrastructure. Its primary function is to reinforce concrete, which is vital in compression but weak in tension. The use of metal rebar compensates for this deficiency, enabling concrete structures to withstand various stresses and strains. This synergy between metal rebar and concrete creates a composite material that efficiently resists both compressive and tensile forces, thereby significantly improving the structural integrity of buildings and other constructions.

How Metal Rebar Strengthens Concrete

The strength of metal rebar for concrete lies in its ability to absorb and distribute tensile forces throughout a structure. When concrete is subjected to tension, it is prone to cracking. However, the incorporation of metal rebar within the concrete matrix allows it to hold the structure together, preventing crack propagation. This is especially crucial in areas prone to seismic activity, where the flexibility and strength of reinforced concrete can mean the difference between a structure standing or collapsing during an earthquake. The metal rebar acts as a skeleton within the concrete, providing thenecessary support and resilience to the structure.

The Ongoing Evolution of Metal Rebar in Construction

The evolution of metal rebar for concrete continues to be an area of technological advancement in the construction industry. Innovations in the composition, shape, and coating of rebar have led to increased durability and corrosion resistance, further extending the lifespan of concrete structures. Modern construction techniques also optimize the placement and spacing of rebar to maximize its effectiveness in reinforcing concrete. As a result, metal rebar remains a fundamental component in construction, continuously adapting to meet the demands of modern architectural designs and environmental challenges.

Innovations in Metal Rebar Manufacturing

The manufacturing of metal rebar has undergone significant transformations over the years, driven by the need for more efficient, durable, and cost-effective construction materials. Early methods of producing rebar were relatively basic, focusing mainly on creating bars of consistent size and strength. However, as engineering and architectural demands have evolved, so too has the process of manufacturing metal rebar. Innovations in metallurgy and industrial processes have led to the development of rebars with enhanced properties, such as greater tensile strength, improved bonding with concrete, and increased corrosion resistance.

Technological Advancements in Rebar Production

Recent technological advancements in metal rebar manufacturing have focused on improving both the material composition and the production process. The introduction of high-strength steel alloys allows for thinner yet stronger rebars, reducing the overall weight of the concrete structures while maintaining structural integrity. Additionally, advancements in manufacturing technology, such as automated casting and rolling processes, have improved the precision and efficiency of rebar production. These developments not only enhance the quality of the final product but also contribute to reducing waste and energy consumption in the manufacturing process.

The Future of Metal Rebar Manufacturing

Looking to the future, the trend in metal rebar manufacturing is towards even more sustainable and environmentally friendly practices. There is a growing focus on reducing the carbon footprint of the production process, with research into alternative, less carbon-intensive methods of producing steel. The use of recycled materials in the production of rebars is also gaining traction. Additionally, the development of intelligent rebars embedded with sensors to monitor the health of concrete structures is an exciting area of innovation, offering the potential for more proactive maintenance and longer-lasting systems. These advancements promise to revolutionize the role of metal rebars in construction further.

Leave a Reply

Want to join the discussion?Feel free to contribute!